If you’re dealing with three-phase motors, you’re likely familiar with a few headaches they can cause. One serious problem exclusive to these motors is unbalanced loads. It’s a common issue, yet it’s often overlooked, leading to reduced motor efficiency and a shorter lifespan.

In this article, I’ll dive into the nitty-gritty of unbalanced loads in three-phase motors. I’ll explain what it is, why it’s a problem, and how it can be identified. More importantly, I’ll share some practical solutions to help you tackle this issue head-on.

So, if you’re keen on boosting your motor’s performance and extending its life, you’re in the right place. Buckle up, because we’re about to get technical.

A Serious Problem Common Only To Three Phase Motors Is

Before we can delve into the problems peculiar to three-phase motors, let’s indeed make sure we’re all on the same page by defining what a three-phase motor is.

Working Principles of Three-Phase Motors

To understand the problems that can arise, we should also take a moment to explain how three-phase motors work.

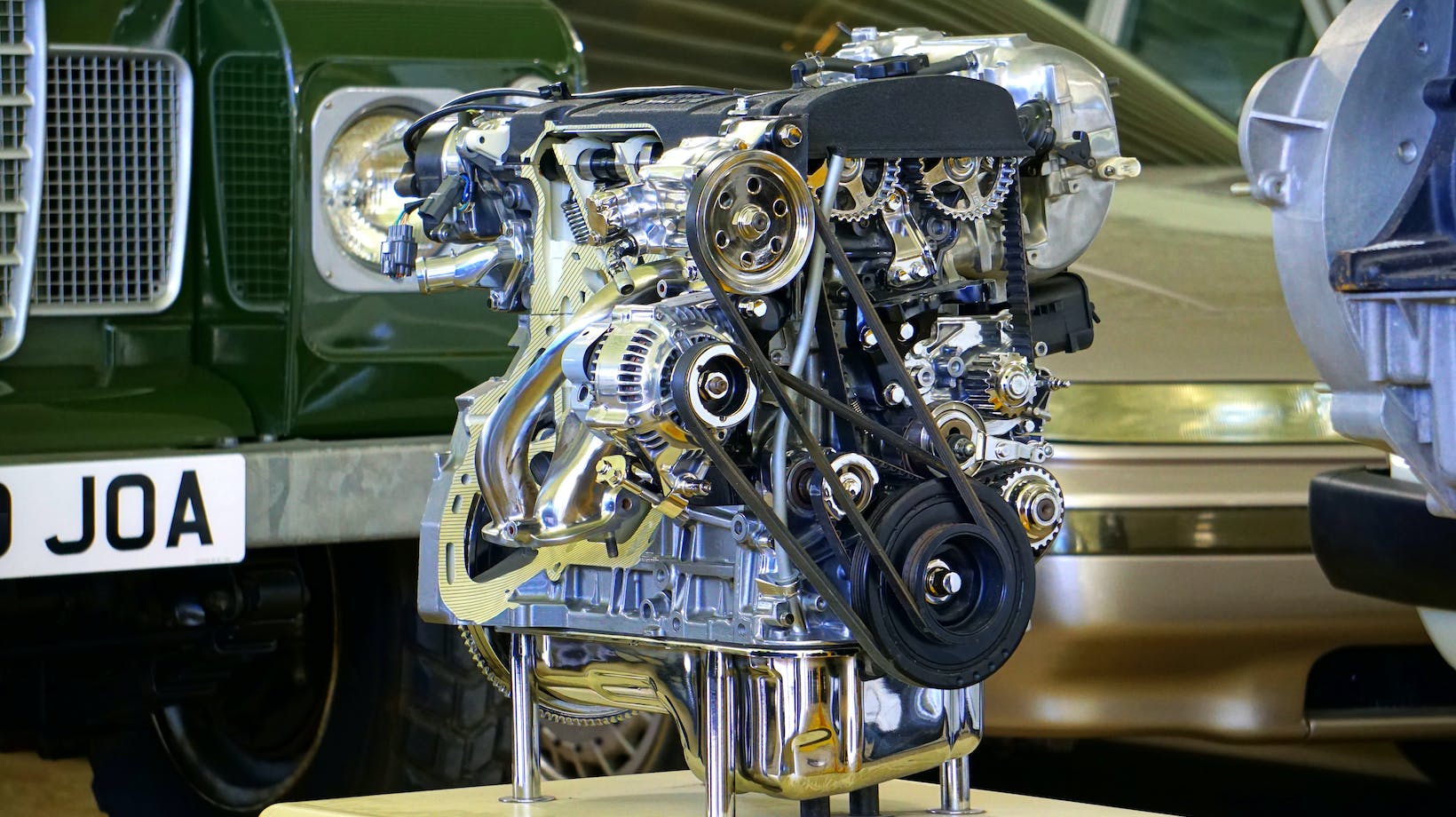

Three-phase motors operate based on the principle of electromagnetism. What happens is that the motor’s stator is given a three-phase, alternating current. This, in turn, generates a rotating magnetic field. The stator’s rotating field interacts with the rotor winding and causes the rotor to rotate according to the motor’s speed, also known as its synchronous speed.

If you’re like me and you prefer a clear visual, think of the rotor as the part that actually does the work, like moving heavy machinery, but it can’t do its job without the rotating magnetic field that the stator generates.

This is where the problem comes in. If there’s any imbalance in the three-phase currents feeding the motor, problems occur. We refer to these as unbalanced loads. Unbalanced loads in three-phase motors can significantly reduce the motor’s efficiency and dramatically shorten its lifespan. That’s why it’s so crucial to quickly identify and immediately address these issues.

Understanding the nature of three-phase motors and their operation principles, sets the stage for a better grasp of the problems and solutions surrounding unbalanced loads in three-phase motors. So let’s move forward and delve into that topic.

Common problems in Three Phase Motors

As we continue to delve into the intricacies of three phase motors, it’s crucial to understand the common issues that could potentially derail their functionality. These problems aren’t to be taken lightly as they can severely diminish the motor’s operational efficiency and lifespan.

Overheating Issues in Three Phase Motors

One of the key issues causing the downfall of many three phase motors is overheating. Heat can be a motor’s worst enemy. It’s true that these motors are designed to handle high load applications, but excessive heat can lead to the breakdown of insulation and other critical components. Overheating might spawn from several sources such as:

- A lack of proper ventilation or cooling systems

- Excessive loads

- Uncontrolled and frequent start-stops

Overheating is a silent killer for three phase motors. It subtly and progressively damages the motor, forcing it towards an early retirement if left unchecked.

Electrical Faults in Three Phase Motors

Next, let’s talk about electrical faults, another relentless troubler in three phase motors. Electrical faults generally manifest in the form of:

- Short circuits

- Ground faults

- Over and under-voltage conditions

Each of these factors can lead to unbalanced loads and consequently, operational inefficiency. The insulation system integrity in the three phase motors is strongly influenced by these electrical faults. Hence, it becomes crucial to detect and rectify them as quickly as possible.

Mechanical Failures in Three Phase Motors

Mechanical failures, though less frequent, are equally devastating. They are often disguised as effects of other issues, making their detection comparatively difficult. They might include bearing failures, rotor imbalance issues, or structural faults.

Preventive maintenance and regular checks play an instrumental role in keeping these mechanical failures at bay and maintaining the optimal efficiency of the three phase motors.

No matter what the specific issue, it’s clear that preventative measures and timely interventions can be life-saving for three phase motors. As we dig deeper into each problem type, I’m sure you’ll start gaining a whole new perspective on your approach towards the maintenance and care of these powerhouses.